Overview

-

-

-

The use of six-face top hydraulic press

Diamond making machine

Hexagonal hydraulic press is an ultra-high pressure equipment for synthesizing superhard materials. It is the main equipment widely used in China's superhard material industry. The six-faceted hydraulic press developed and designed by Hanfa Group has safety and stability, simple operation, convenient maintenance, and significant economic benefits. Features.

This equipment is mainly used for the production and research of superhard materials such as synthetic diamond, cubic boron nitride single crystal and polycrystalline, synthetic composite

-

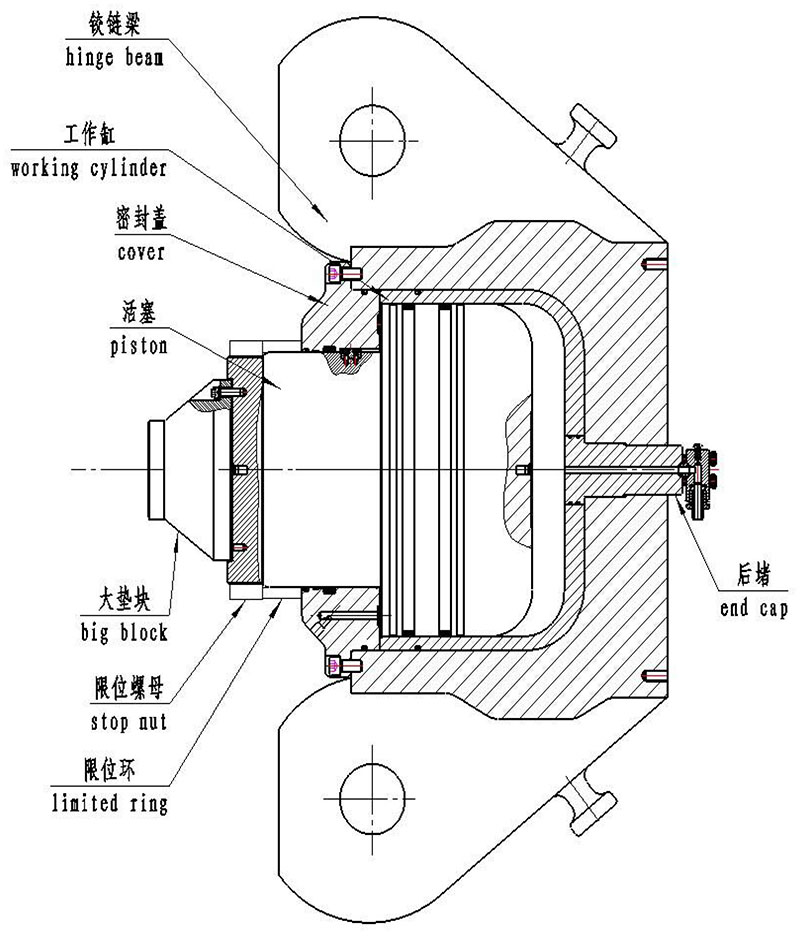

Cylinder press on six sides

Features: high strength, high rigidity, and high pressure.

Disadvantages: The cost of the same cylinder diameter is higher than that of a cylinderless compressor, and the design pressure is 120MP.

-

-

Types and characteristics of UHV

1. Supercharger overpressure

The traditional overpressure form has advantages: low noise, low failure rate and super stability; disadvantages: large volume, high initial investment cost, and limited overpressure volume.2. Overpressure of ultra-high pressure pump

Advantages: simple structure, suitable for various technological forms.

Disadvantages: high noise, high power, limited by the production quality of the pump.

Configuration: 2-3 motors, motor power 5-20KW. (Appropriate adjustments will be made according to the cavity and process).3. Overpressure of double-acting reciprocating supercharger

Advantages: low noise, small size, convenient installation, suitable for various process forms.

Disadvantages: unstable service life.4. Advantages of flushing type supercharger: small size, low noise, low failure rate, good stability, suitable for various technological forms. Disadvantages: need a second pressure relief.

5. There are two commonly used overpressure methods:

a) Supercharger overpressure.

b) The ultra-high pressure pump is overpressured. -

-

The use of six-face top hydraulic press

Hexagonal hydraulic press is an ultra-high pressure equipment for synthesizing superhard materials. It is the main equipment widely used in China's superhard material industry. The six-faceted hydraulic press developed and designed by Hanfa Group has safety and stability, simple operation, convenient maintenance, and significant economic benefits. Features.

This equipment is mainly used for the production and research of superhard materials such as synthetic diamond, cubic boron nitride single crystal and polycrystalline, synthetic composite

-

Hydraulic system

1. The composition of the hydraulic system

a. According to its oil circuit, it can be divided into two parts: main oil circuit and control oil circuit.

The main oil circuit is bounded by an ultra-high pressure controllable one-way valve, which can be divided into two parts, high-pressure and ultra-high-pressure oil circuits. The high-pressure oil circuit is 10-28 (MPa), which is composed of an axial piston pump and general high-pressure hydraulic components. The ultra-high pressure oil circuit is composed of a two-position seven-way valve, an ultra-high pressure controllable one-way valve and an ultra-high pressure one-way valve. The pressure of the ultra-high pressure oil circuit is below 120MPa.

b. According to its appearance, it is divided into the following 2 parts

The ultra-high pressure part of the main engine: It is composed of an ultra-high pressure controllable one-way valve, an ultra-high pressure one-way valve and a two-position seven-way valve, and is connected to the six-side top host by an ultra-high pressure pipeline.

High-pressure control part: consists of hydraulic station and power part. Developed according to the changes in the ultra-high pressure part. Connected to the ultra-high pressure part by hose or steel pipe.

2. Features of hydraulic part

Scientifically divide the hydraulic system to complete off-site production of ultra-high pressure pipes. The whole machine can be installed with dual oil filtering systems to keep the oil circuit clean. The overall layout is neat and plug-in connection with the electronic control system. It is quick to install and easy to maintain and maintain. It is beneficial Normal production equipment management.

3. Hydraulic configuration

Working pressure: ultra-high pressure max 120MPa.

System pressure max:

The ultra-high pressure pump is configured to 12Mpa, and the supercharger is 15Mpa.

Return pressure max: 5MPa (adjustable range 1.5-8MPa).

Mainly equipped with power: (the plunger pump will be adjusted appropriately according to the size of the cylinder diameter).

Plunger pump: 63/80 SCY14-1B supporting motor: 10-20KW; 10SCY14-1B supporting motor: 4Kw.

Pressure relief method: a. Proportional type: realizes three-stage unloading and meets the existing mainstream synthetic pressure relief requirements.

b. Curve type: also known as servo pressure relief, which can achieve arbitrary curve pressure relief and meet mainstream pressure relief requirements and special pressure relief requirements.

c. Compound type: comprehensive proportional and curved pressure relief, which basically meets all requirements of industrial synthetic pressure relief.

d. Gem-grade type: high-precision pressure relief, more in line with the synthetic process curve, and small pressure fluctuations.

Main valve diameter: 16 diameter of electro-hydraulic reversing valve, 10 diameter of electromagnetic reversing valve.

-

-

Electric control system

The main technical parameters

a. Range and range

Working environment temperature: -10-50℃

Control part voltage: 180~250 V(AC)

Pressure detection range: 150 MPa

Heating current control range: 5000A-6000A

Heating voltage control range: 10V-12 V

Heating power control range: 32 kw

Detection range of displacement potentiometer: 200mm

Dynamic response time: <0.1s

Transformer configuration: 40-70KVA output: 7V, 10V

Copper braided wire: 1200-1500mm2 1.5m+1.8m

b. Precision and resolution

Pressure detection accuracy: 0.2 level Display resolution: 0.01MPa

Primary current accuracy: 0.2 level Display resolution: 0.01A

Secondary current accuracy: 0.2 level Display resolution: 1A

Heating voltage accuracy: 0.2 level Display resolution: 0.001V

Synthetic resistance resolution: 0.001 milliohm

Displacement sensor accuracy: 0.05mm display resolution: 0.01mm

Power adjustment accuracy: 1W Display resolution: 0.001kW

-

TECHNICAL DATA

| model | HFYG600 | HFYG650 | HFYG700 | HFYG750 | HFYG800 | HFYG850 |

| Hinge beam diameter | 600mm | 650mm | 700mm | 750mm | 800mm | 850mm |

| Piston diameter | 600mm | 650mm | 700mm | 750mm | 800mm | 850mm |

| Design pressure | 120Mpa | 120Mpa | 120Mpa | 120Mpa | 120Mpa | 120Mpa |

| Single cylinder pressure | 33.91MN | 39.8MN | 46.2MN | 52.99MN | 60.3MN | 68.06MN |

| Nominal pressure | 95Mpa | 95Mpa | 95Mpa | 95Mpa | 95Mpa | 95Mpa |

| Nominal single cylinder thrust | 26.84MN | 31.51MN | 36.55MN | 41.95MN | 47.8MN | 53.9MN |

| Maximum opening height | 680mm | 752mm | 812mm | 904mm | 990mm | 1080mm |

| Maximum closed height | 530mm | 572mm | 632mm | 714mm | 800mm | 898mm |

| Limit stroke | 75mm | 90mm | 90mm | 95mm | 95mm | 91mm |

| (Recommended top hammer: top hammer longitude x hammer surface) | Φ127*46 | Φ150*51 | Φ160*61 | Φ165*62 | Φ175*62.5 | Φ185*64 |

| Recommended diamond synthesis cavity | 35mm | 40mm | 50mm | 51mm | 51.5mm | 53mm |

| Recommended composite cavity | 32mm | 37mm | 47mm | 48mm | 48.5mm | 50mm |

| Dimensions | 2602x2602x3152 mm | 2782x2782x3332 mm | 2882x2882 x 3432 mm | 2972x2972x 3522mm | 3200x3200x3750mm | 3312x3312x 3862mm |

| Net total press | 34.2t | 47.5t | 53.2t | 61.53t | 73.64t | 82.8t |

RELATED PRODUCTS

Inquiry

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.